Products

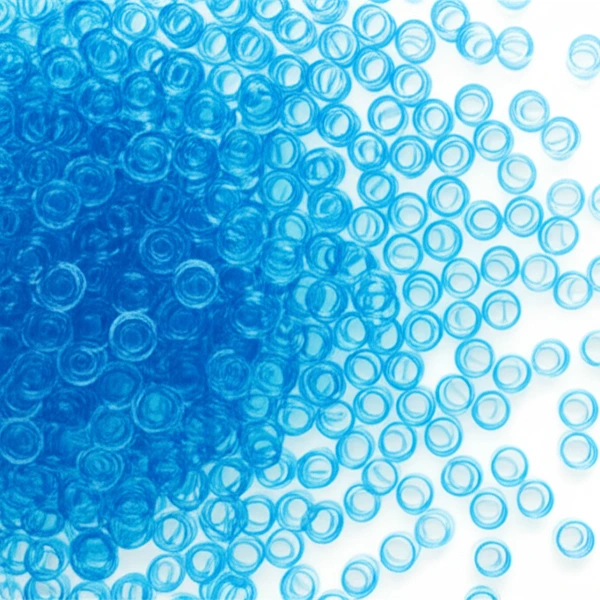

Polypropylene - PP

Polyethylene can be classified into several types based on the density of the plastic and the degree of branching in its structure. The type of branching and the degree of branching have a direct impact on the mechanical properties of the plastic. Therefore, different types of polyethylene exhibit different mechanical properties. Some of the important types of polyethylene are listed below.This polymer is divided into several major categories depending on the type of catalyst used, the comonomer added during polymerization, and the molecular weight:High-density polyethylene (HDPE): It has high density and high mechanical strength. This type of polyethylene is resistant to shock, corrosion, moisture, and temperature changes. HDPE applications include piping, tanks, bottles, packaging, the automotive industry, and construction. Stretch film is an example of high-density polyethylene used in packaging.

Low-density polyethylene (LDPE): It has a lower density and greater flexibility than HDPE and MDPE. This type of polyethylene has high transparency, flexibility, electrical insulation and good bulk properties. LDPE applications include packaging films, bags, agricultural pipes, kitchen coatings, cosmetics and hygiene products, etc. Linear low-density polyethylene (LLDPE): Linear low-density polyethylene (LLDPE) includes a wide range of polyethylenes from clear and elastomeric to opaque and rigid and dry. These grades are used when high stiffness and strength are desired along with low density and high flexibility. An important application of LLDPE is in the production of plastic films such as blown film, cast film, extrusion coating and food packaging.